The comparison between two different EPDM Gym Floor Mats

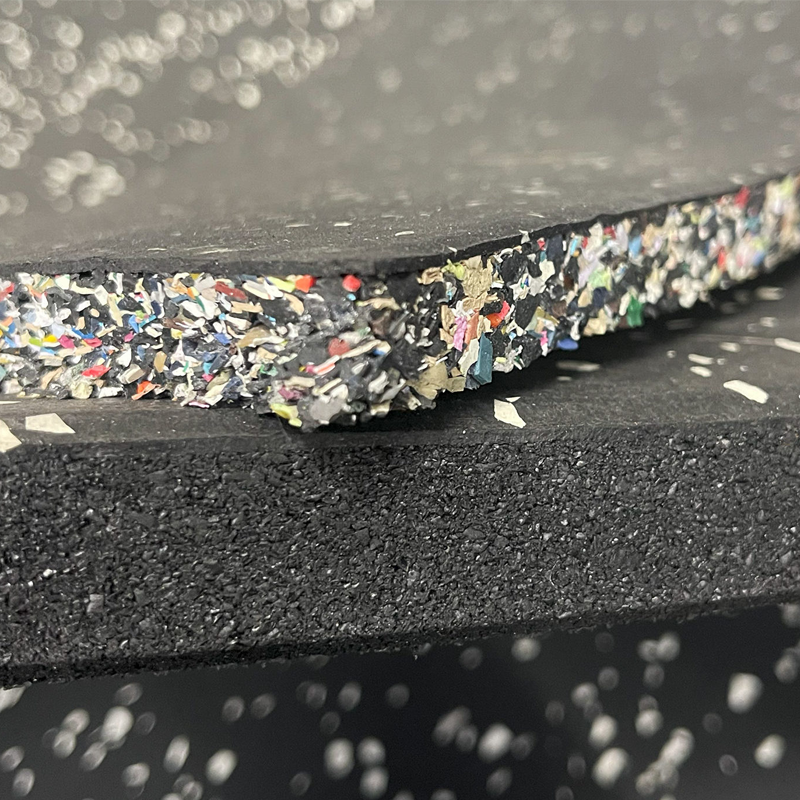

EPDM gym floor mats are rapidly gaining popularity in the market. These mats consist of a robust rubber sheet made of EPDM, and underneath this sheet, two primary rubber materials are used: recycled tyre rubber particles and recycled shoe sole rubber particles. The comparison between recycled tyre rubber particles and recycled shoe sole rubber particles for gym mats depends on various factors and requirements. Here are some considerations:

Durability: Both recycled tyre rubber particles and recycled shoe sole rubber particles can offer durability to gym mats. However, recycled tyre rubber particles are often known for their exceptional strength and resilience, as tyre rubber is engineered to withstand the rigours of the road. Tyre rubber particles are typically derived from used tyres, which are designed to endure harsh conditions and provide long-lasting performance. This makes recycled tyre rubber a popular choice for gym mats that will experience heavy use and impact.

Shock Absorption: Recycled tyre rubber particles are known for their excellent shock absorption properties. The natural elasticity and cushioning ability of tyre rubber can help reduce the impact on joints and minimize the risk of injuries during physical activities. This makes mats using recycled tyre rubber particles a suitable choice for gym and fitness environments where shock absorption is crucial, such as weightlifting areas or aerobic exercise spaces.

Easy Maintenance: EPDM rubber mats are relatively easy to clean and maintain. They are resistant to staining and can be easily wiped or mopped clean using mild detergents or cleaning solutions. Additionally, their non-porous nature prevents the growth of mould, mildew, and bacteria.

Density: Tyre rubber typically contains a higher proportion of reinforcing materials, such as carbon black and other fillers, which can increase the density of the rubber particles. These fillers contribute to the durability and performance of tyre rubber but also increase its density. Shoe sole rubber, on the other hand, is often formulated to be lighter and more flexible, prioritizing comfort and cushioning over high density. Shoe sole rubber may contain fewer reinforcing materials and have a lower density compared to tyre rubber.

Slip Resistance: Tyre rubber is typically harder and more durable than shoe sole rubber. The harder compound provides better resistance to wear and tear, maintaining its grip for longer periods. Shoe soles, on the other hand, are often made with softer rubber to provide cushioning and flexibility, which can sacrifice some durability and grip.

Small Rubber Particles VS Big Rubber Particles: In general, floor mats made of small rubber particles tend to have a higher density compared to mats made of larger rubber particles. This is because smaller rubber particles can pack more closely together, leading to a higher concentration of rubber material per unit volume.

When manufacturing floor mats, rubber particles are typically mixed with binding agents or adhesives and then compressed or moulded into the desired shape. With smaller rubber particles, there is a greater surface area available for the binding agents to interact, resulting in stronger cohesion and denser mat construction.

Additionally, smaller rubber particles can fill gaps and voids more effectively, resulting in a more uniform and compact mat structure. This denser construction can contribute to improved durability, better resistance to wear and tear, and enhanced performance characteristics such as slip resistance.

Please take a moment to review our premium selection of gym floor mats. Our products are specifically designed to meet the highest standards of quality and durability.